Like many others who work in the collision repair industry, you could say Tony Simon grew up in a body shop. His great-grandpa, grandpa, dad and brothers all worked on vehicles, in some form or another.

Simon had a passion for cars and turned that into a long-term career where he had the opportunity to work internationally, bring I-CAR training to China and meet some of the most dedicated collision repairers along the way. Here is his story, as told to Stacey Phillips.

I was born in Dallas, TX. After World War II, my dad worked on John Deere tractors until he was hired at Ed Mauer Ford repairing and painting vehicles. We lived in a house with a very large garage where he repaired what they called “re-builders.”

Working nights and weekends at his home shop, Dad saved enough money to open his first body shop. I spent my free time on weekends and summers at his facility. I swept the floor, cleaned the toilets, anything to be there. I admired the way people repaired and painted vehicles.

When I was about 10 years old, I proudly announced to my dad that I had sanded a vehicle and it was ready to paint. Not having any vehicles that needed to be painted, my dad rushed into the shop and found that I had used an air sander on the entire body of a customer’s freshly-painted vehicle waiting for delivery. To say the least, he wasn’t thrilled.

My dad hired young guys from the local Dallas tech school---Industrial Training Co-operation (ICT). Rudy, a painter and body man at the shop, had attended this program. He taught me how to paint, along with my dad and older brother and mentor, Fred.

Fred was my inspiration. We worked together for 20 years and he provided me with the skills and knowledge that I have depended on throughout my life.

In 1956, my dad built three custom pickups out of passenger vehicles, one of which was a 1956 Mercury. I bought that vehicle and performed some radical custom bodywork features with Fred’s help. I worked on it for three years during high school, driving it during all stages of work.

“Tony was born to be a body man. Even as a child, he was drawing custom cars. By the time he was in junior high, he worked at his dad’s body shop after school and Saturdays. Then on Sunday, he would go with his dad and brother to the drag strip where he worked with the pit crew. Tony has incredible hands that can fix or build anything he visualizes.” — Don Doak, lifelong friend

In 1961, my parents gave me all the necessary materials from House of Kolor to paint the truck Candy Burgundy. Once completed, I entered it into custom car shows, winning first place in the category of radical custom at the Daryl Starbird’s custom car show in Dallas in 1962.

By this time, I was the shop’s head painter. I also performed collision repair work, but I painted all the vehicles. We were called combination men back then.

We began to repair heavy-duty trucks in 1964 for a company that brought their trucks to us from West Texas, New Mexico and Colorado. Soon after, we stopped working on passenger vehicles. As the business grew, we needed more shop space and upgraded our equipment.

We also conducted time and motion studies for Mitchell information system’s heavy-duty truck manual. We were classified as field consultants.

Shop employees were hard to come by, as not many people worked on heavy trucks. Few auto techs wanted to make the transition. As a result, we developed an in-shop training program for repair procedures starting in the late 1960s.

A man named Kevin Costner came to work for us after graduating from high school in 1979 and became a trusted employee. Kevin is currently a technical trainer at Gerber Collision.

“Tony is a dreamer. He envisions a project and sees it through. He doesn't take rejection as a stopping point. He works around it. Tony taught me to see the world much differently… that there are no restrictions in life. I can be the best I can be at repairing vehicles and being a human being.” — Kevin Costner

In 1983, my dad retired, so my brother and I closed the truck shop and I moved to Kauai, HI. I worked as the body shop manager at Kuio Motors, a small GM/Nissan dealer on the island’s south side.

We moved back to Texas in 1985. I began working as a body man for a year at an independent shop until I opened Simon Company Body Shop in 1986.

At one point, my shop became a partner with Allstate Insurance in their new direct repair program (DRP) called Pro Shop. It was a very simple process. They faxed a claim number, we faxed an estimate and mailed a photo, and they mailed a check to us.

As my business grew, I opened another shop nearby in 1987 to handle the work volume. Kevin began working with us again.

Unfortunately, I needed to close my shops in 1991 due to a divorce. In 1996, I was hired as a body tech at a local GM dealership where I worked for two years. During this time, I attended my first I-CAR class taught by Johnny Dickerson and Merl Wertz.

I became interested in becoming an instructor and I contacted the I-CAR southwest regional manager, Doug Middleton, to begin that journey. When Doug retired, Jeff Peevy came on board as the regional manager. He currently holds the position of vice president, Technical Products, Programs & Services at I-CAR.

My goal was to work at the GM shop for two years and move to New Zealand, which I did in 1998. I found a job in a panel beater shop (body shop) by calling the consulate in California and asking if they could mail me copies of the New Zealand yellow book pages.

After a couple of calls, I found a shop that participated in I-CAR training---A1 Paint and Body in Auckland, North Island, NZ. I spoke with Brent Mckay, the partner general manager, about my desire to work there. He agreed, but I’m sure he thought I would never show up.

About six months and several calls later, I arrived at the facility. I worked in the paint shop as a prepper and eventually performed collision repair work while attending I-CAR classes. I also taught panel bonding on the North Island for New Zealand I-CAR.

When my father passed away in 2000, I returned to the U.S. from New Zealand. Jeff asked if I would conduct I-CAR classes for him in the Phoenix, AZ, and East Texas areas.

“Tony has a genuine dedication to educating the industry and will go to extreme lengths to make it happen. Once, while preparing for an I-CAR regional conference, Tony drove 100 miles one way just to help load boxes because I had hurt my back. Tony never sought recognition for all the work he has done for the industry over the years. He simply just wanted to see that people learned things they needed to know.” — Jeff Peevy

Several times, I drove non-stop from Arizona to Texas for a class in Ft. Worth and only had two students. To help solve the low-attendance problem, we came up with a plan under the I-CAR Fort Worth committee leadership of Dave Gauthier---to arrange some sponsors and give away two free classes. We held an awareness event called The I-CAR EXTREME and taught 237 students at one time.

One of the sponsors was Tim Curran, owner of Car-O-Liner Southwest Company. Tim asked Ron Olsson, president of Pro Spot International, to donate a demonstration spot welder as Tim sold both brands.

Pro Spot sent a spot welder and an engineer, Bob Pulth, from the company’s California factory to demonstrate how to use it because spot welding was a new technology to the collision industry back then. The demonstration included a chemist from Lord Fusor, who replaced a quarter panel with weld bonding prepared by Kevin and his team. Since that first event, many similar types of programs have been conducted.

“Tony has definitely been a gifted teacher and very generously contributed his time and knowledge with many technicians over the years. Tony will always be remembered as a true pioneer with I-CAR and its training mission.” — Tim Curran

I had wanted to visit China since President Nixon traveled there. I learned that Car-O-liner was going to sell equipment in China, so I asked Tim to introduce me to Car-O-Liner’s international sales rep. I arranged a meeting with the rep at the Automechanika show in Frankfurt, Germany, the following year and developed a plan.

Car-O-Liner had a relationship with Shandong Jiatong University in China and provided them with a frame machine and measuring equipment. The school operated a shop on campus but did not use the equipment. The rep thought I could help him train the school and encourage them to use the equipment.

The rep and I met again in Beijing in March 2001 and he introduced me to the school leaders. I made an agreement with the school to teach the students English while I also traveled for them, lecturing about collision repair.

The following summer, I lectured at a China automobile association meeting in Yantai on the east coast. I met a lot of leaders and spoke on the use of 75/25 gas in MIG welding. At that time shops had MIG welders but bought 100% CO2 gas to weld with because it was cheaper.

One of the attendees was the China National Model for collision repair shops, Mr. Wei. He understood the meaning of my lecture and began to change his shops over to 80/20 gas. This has been my main measure of success working in China.

A teacher at the school knew that I had lived and worked in New Zealand and introduced me to Xiangyun Zheng (Sue), an English major at Shandong University in Jinan, who had a desire to go to New Zealand to study.

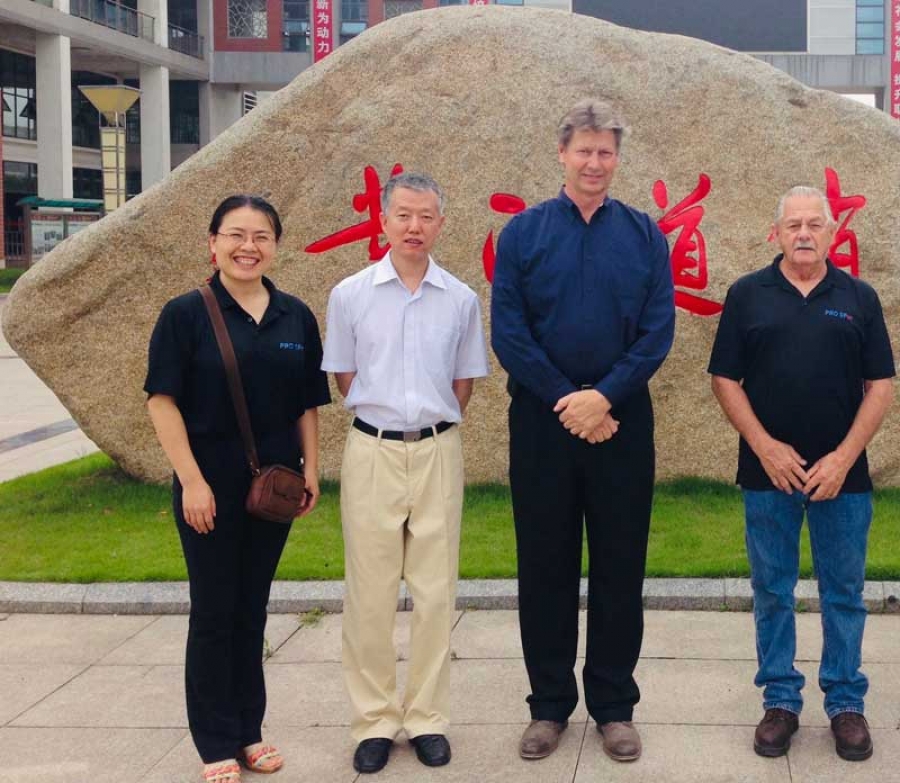

Sue lived on campus with her family and worked as a trainer and translator. Shortly after we met, I asked Sue to travel with me to a lecture and be my interpreter.

Sue’s father was a professor at the transportation university. Sue studied the books her father gave her and the I-CAR material I provided, as well as learned from the lectures we attended together. She is now considered by many to be the most knowledgeable translator in the Chinese collision repair industry.

In 2004, the Chinese government asked Sue and me to conduct an 11-month training program in 40 cities for the China Automobile Maintenance and Repair Association (CAMRA). As part of the program, there was a competition. We trained 120 students in each city. The competition was a new endeavor for the collision industry in China and still takes place today.

The students measured and pulled, MIG welded and spot-welded with a Pro Spot PR-2000 welder donated by Ron Olsson.

Sue received her U.S. visa in 2005. Since then, we have traveled back and forth to China to focus on collision repair training and testing. We also taught in Taiwan and mainland China for AIG insurance.

“When Tony headed to China, I don’t believe he knew anyone. He overcame the culture and language and I feel he even helped the collision industry there with training and his relationships with equipment companies here in the U.S.” — Kevin Costner

In 2006, we attended the I-CAR annual meeting in Scottsdale, AZ, and Jeff suggested that we meet with the head of the I-CAR weld test program about a new pilot program where testing was conducted in shops rather than schools.

In addition to being president of Pro Spot, Ron was an I-CAR board member and happened to be attending the conference. I asked if he could provide a trailer and welders for the pilot program and he said yes.

Ron had recently sold welders to Sterling Auto Body and needed to provide MIG and spot-welding training for each of the 57 shops. Sue and I mapped a route of all the locations, found all the Gold Class shops along the way and faxed ahead to see if any of the shops wanted the tests performed.

Most people thought we were scammers as no one had heard of in-shop weld testing. We traveled more than 15,000 miles to 110 cities in 42 states over 10 months. Until October 2018, we spent 250 or more nights a year in a hotel on the road training and testing.

I-CAR then asked that we work as consultants with their China endeavor. Over the years, many people and companies have requested that I-CAR train in China.

We introduced I-CAR to some of our business friends in China and began to arrange face-to-face meetings in 2019 where Sue acted as the translator. Unfortunately, the COVID-19 virus began to spread and that ended all the work, here and in China.

I hope the industry recognizes what a great opportunity that I-CAR has given our industry to gain the knowledge to repair today’s complex vehicles.

Without I-CAR and the great people who are part of their leadership team, like John Van Alstyne, CEO and president, and Jeff Peevy, our industry wouldn’t be the same.

Stacey Phillips Ronak